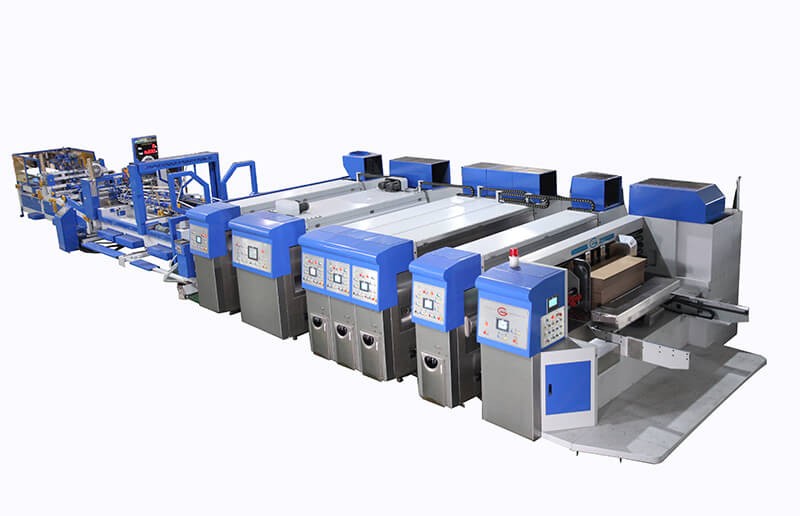

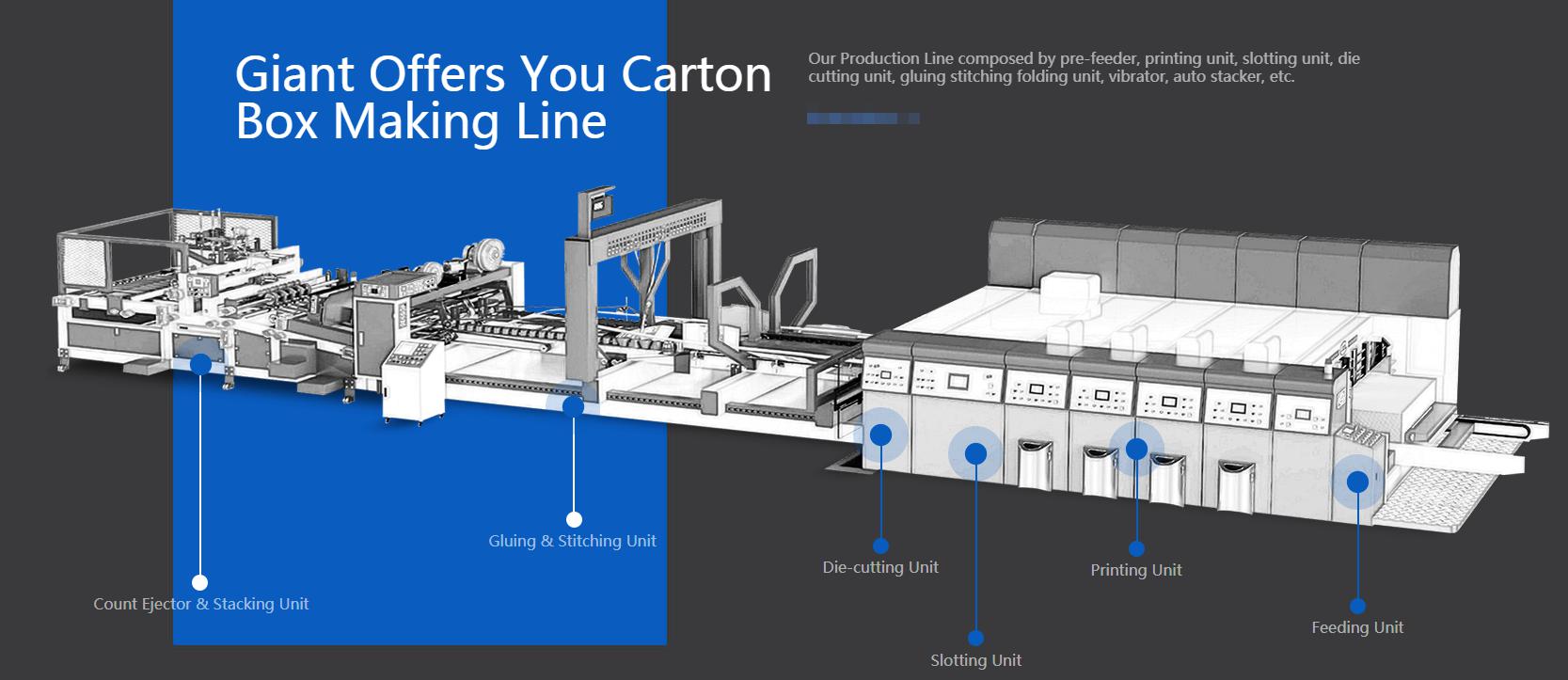

Various corrugated carton making machines

Various corrugated carton making machines

Angle cutting blade equipped with coil spring structure, ensure the all scrap cut down and drop cleanly...

1. Feeder Unit

1.1 Photo

2.1 Technical Parameter

| Feeding system | Lead edge Feeding system |

| Zero position | Automatic |

| Total counter | Touch screen display |

| Machine speed | Touch screen display |

| Sheet clearer | Suction bolower & brush for sheet cleaning |

| Side guide position | Motorized , 0.2kw×2ea, Touch screen display |

| Front stop position | Motorized , 0.1kw , by jog switch |

| Back stop position | Motorized , 0.2kw , by jog switch |

| Feed roll nip control | Motorized , 0.2kw , Touch screen display |

| Unit open/close | Motorized , 0.4kw , by jog switch |

| Lower suction blower | 7.5 kw |

| Main motor | Inverter control : 37kw |

* detail technical parameter can be provide if need

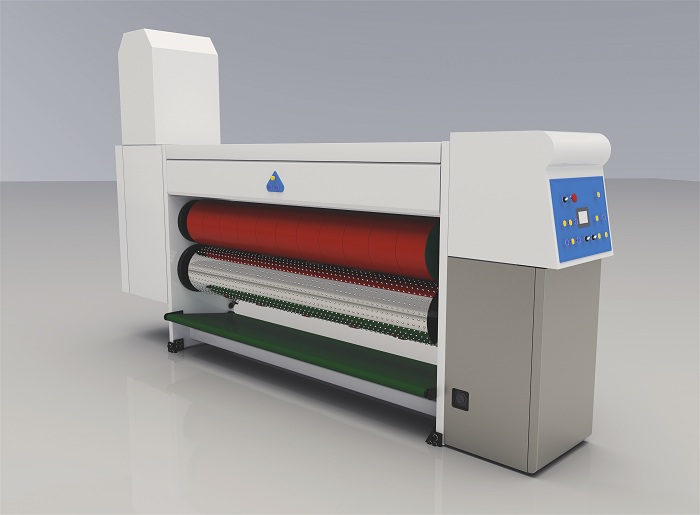

2. Printer Unit

2.1 Photo

2.2 Technical Parameter

| Top printing system | optional |

| Bottom printing system | optional |

| Vacuum transfer system | optional |

| Ceramic anilox roller | optional |

| Chamber Doctor blade | optional |

| Doctor roller inking system | Diaphragm type ink pump |

| Register System | Printing register is digital controlled by motor and PLC |

| Easy to control by means of reset "0" system | |

| Zero position | Automatic |

| Print cylinder register | Motorized 0.4kw , Touch screen display |

| Print cylinder side control | Motorized 0.2kw , Touch screen display |

| Impress roll nip control | Motorized 0.2kw , Touch screen display |

| Pull roll nip control | Motorized 0.2kw , Touch screen display |

| Anilox roller clearance | Motorized 0.1kw , Touch screen display |

| Doctor roller clearance | Motorized 0.2kw , Touch screen display |

| Doctor roller motor | Geared 0.4kw |

| Gear box oil level | Automatic control (All unit the same) |

* detail technical parameter can be provide if need

3. Slotter Unit

3.1 Photo

3.2 Technical Parameter

| Dual slot system | No need mechanical adjustment for bigger carton height |

| Zero position | Automatic |

| Panel size | Motorized(0.4kw x 4ea), Touch screen display |

| Slot depth size | Motorized(0.4kw), Touch screen display |

| Box height size | Motorized(0.4kw), Touch screen display |

| Cleaser nip control | Motorized , 0.2kw , Touch screen display |

| Slotter nip control | Motorized , 0.2kw , Touch screen display |

| Scrap conveyor | 0.4kw |

* detail technical parameter can be provide if need

4. Die-cutter Unit

4.1 Photo

4.2 Technical Parameter

| Zero position | Automatic |

| Die roll register | Motorized 0.4kw ,Touch screen display |

| Die roll side control | Motorized 0.2kw ,Touch screen display |

| Anvil roll transversal movement | Automatic 70mm |

| Anvil roll clearance | Motorized 0.4kw ,Touch screen display |

| Pull roll nip control | Motorized 0.2kw ,Touch screen display |

| Scrap conveyor | 0.4kw |

* detail technical parameter can be provide if need

5. Gluer / Stitcher Folder & Count Ejector Unit

5.1 Photo

5.2 Technical Parameter

| Down folding system | Optional |

| Up folding system | Optional |

| Belt transportation system | With guide, bar leads the carton box and makes folding more accurate |

| Box squaring system | |

| Main motor | AC 15kw, inverter control |

| Side guide positation | 0.4kw X 2ea, touch screen display |

| Glue head position | 0.4kw X 1ea, touch screen display |

| Pusher | 0.75kw |

| Suction blower | 2.2kw X 2ea, 1.5kw X 1ea |

| Bottom stacking system | The boxes stack from bottom to top |

| Suction belt conveyor | For the best conveying accuracy |

| Count ejector system | For high speed production |

| Main motor | 7.5kw |

| Front stop position | 0.4kw, touch screen display |

| Back stop position | 0.4kw, touch scereen display |

| Ejecting line control | Touch screen display |

| Center line control | 0.4kw |

| Suction blower | 2.2kw |

| Belt conveyor | 0.75kw |

| Model | Panel size | L x W | A | B | C | Max. Speed | |

| GMFG-0718 | Max. | 1800x700 | 350 sheet/min | ||||

| Min. | 560x270 | ||||||

| GMFG-0818 | Max. | 1800x800 | 300 sheet/min | ||||

| Min. | 560x280 | ||||||

| GMFG-0820 | Max. | 2000x800 | 300 sheet/min | ||||

| Min. | 560x280 | ||||||

| GMFG-0920 | Max. | 2000x900 | 260 sheet/min | ||||

| Min. | 560x290 | ||||||

| GMFG-0924 | Max. | 2400x900 | 260 sheet/min | ||||

| Min. | 560x290 | ||||||

| GMFG-1020 | Max. | 2000x1000 | 240 sheet/min | ||||

| Min. | 600x300 | ||||||

| GMFG-1024 | Max. | 2400x1000 | 240 sheet/min | ||||

| Min. | 600x300 | ||||||

| GMFG-1224 | Max. | 2400x1200 | 220 sheet/min | ||||

| Min. | 640x320 | ||||||

| GMFG-1228 | Max. | 2800x1200 | 200 sheet/min | ||||

| Min. | 640x320 | ||||||

| GMFG-1428 | Max. | 2800x1400 | 180 sheet/min | ||||

| Min. | 680x350 | ||||||

| GMFG-1628 | Max. | 2800x1600 | 150 sheet/min | ||||

| Min. | 680x400 | ||||||

For detail parameters, please feel free to contact.